If you’re exploring how pharmaceutical formulations achieve greater stability and performance, understanding the role of tyloxapol USP can provide clear insights into its real-world applications.

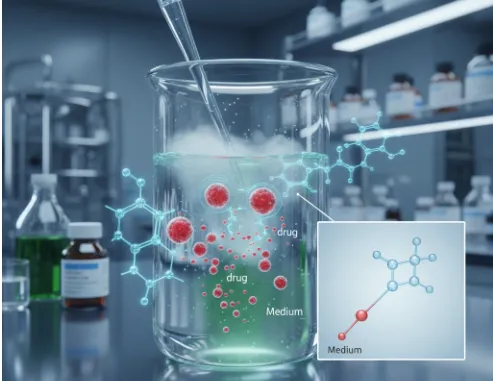

In pharmaceutical formulations, achieving stability and uniform performance is a constant challenge. Ingredients like tyloxapol USP help formulations remain consistent and effective throughout their shelf life. They also play a key role in improving the overall solubility and dispersion of active ingredients.

Surfactants are commonly used to improve how ingredients mix and behave in liquid and semi-liquid medicines. Tyloxapol is widely used because it works gently without reacting with active ingredients, making it suitable for sensitive pharmaceutical applications.

Manufacturers also rely on proper identification and compliance when selecting formulation components. The reference 25301 02 4 helps ensure traceability and consistency, which is essential in regulated pharma environments where accuracy and safety matter most.

What Is Tyloxapol USP

Tyloxapol USP is a pharmaceutical-grade excipient commonly used as a surfactant in drug formulations. It helps different ingredients blend smoothly, ensuring uniformity in liquid and semi-liquid medicines.

This compound is non-ionic, meaning it does not carry a charge. Tyloxapol works gently within formulations, reducing the risk of unwanted reactions with active pharmaceutical ingredients.

In regulated pharmaceutical manufacturing, proper identification is essential. The reference 25301 02 4 is used to ensure traceability, quality consistency, and compliance with industry standards, helping manufacturers maintain accuracy and reliability in their formulations.

Understanding Non-Ionic Surfactants in Pharmaceuticals

Non-ionic surfactants are widely used in pharmaceutical formulations because they improve ingredient compatibility and stability. Tyloxapol USP is commonly chosen for its gentle action and reliable performance.

- Help disperse insoluble ingredients evenly in liquid formulations.

- Reduce surface tension to improve mixing and uniformity.

- Maintain formulation stability without altering drug effectiveness.

- Support consistent texture and appearance in finished products.

- Perform well across a wide range of formulation conditions.

By supporting smooth blending, these surfactants help improve product reliability. The use of tyloxapol allows manufacturers to achieve consistent results in sensitive pharmaceutical applications.

How Tyloxapol USP Works in Pharma Applications

In pharmaceutical formulations, tyloxapol USP facilitates smooth interaction among ingredients that do not naturally mix well. Its non-ionic nature allows it to function without interfering with drug stability.

- Improves Dispersion:

It helps evenly distribute active ingredients in liquid and semi-liquid formulations, preventing settling over time.

- Enhances Solubility:

Tyloxapol helps break down particles, allowing poorly soluble substances to blend more effectively.

- Supports Emulsion Stability:

It keeps oil and water-based components uniformly mixed, ensuring consistent texture and appearance.

- Maintains Formulation Balance:

The surfactant works without altering the chemical structure of sensitive pharmaceutical compounds.

- Ensures Batch Consistency:

The identifier 25301 02 4 supports accurate selection and repeatability during formulation processes.

Through better ingredient compatibility, this surfactant plays a key role in maintaining formulation reliability. Its stable performance makes it a practical choice for multiple pharmaceutical uses.

Key Pharmaceutical Applications of Tyloxapol USP

In pharmaceutical manufacturing, achieving smooth and stable formulations requires carefully selected excipients. Tyloxapol USP is often chosen for applications where ingredient compatibility and controlled dispersion are critical. Its performance remains reliable across different formulation environments.

- Oral liquid medicines

- Suspension-based formulations

- Inhalation and respiratory products

- Liquid topical preparations

- Oil-in-water pharmaceutical systems

Its role in supporting uniform mixing helps reduce formulation issues during storage and use. Tyloxapol remains in use across multiple pharmaceutical applications due to its consistent performance.

Benefits of Using Tyloxapol USP in Drug Formulations

Pharmaceutical formulations often require excipients that perform consistently without disrupting active components. Tyloxapol USP supports this requirement by enabling smoother formulation behaviour under controlled conditions.

- Helps keep active ingredients evenly distributed over time.

- Limits formulation changes during storage and handling.

- Supports repeatable results across multiple production cycles.

- Allows better control during mixing and processing stages.

- Remains stable when used alongside sensitive compounds.

These advantages help reduce formulation challenges during manufacturing and storage. With the use of tyloxapol, pharmaceutical products can maintain expected performance throughout their intended use.

Quality and Compliance Considerations

Ensuring high-quality pharmaceutical formulations requires careful selection of excipients, such as tyloxapol USP. Compliance with regulatory standards is essential for both safety and consistency in drug production.

- USP Compliance:

Using tyloxapol USP that meets USP standards ensures the excipient adheres to strict quality and purity requirements, making it suitable for pharmaceutical use.

- Traceability with 25301 02 4:

The unique identifier 25301 02 4 helps manufacturers track and verify batches, ensuring formulation accuracy and regulatory adherence.

- Safe Handling and Storage:

Proper storage conditions and handling protocols prevent contamination and degradation, maintaining the excipient’s effectiveness.

- Regulatory Alignment:

Selecting certified tyloxapol ensures that formulations comply with local and international regulations, reducing the risk of recalls or compliance issues.

- Consistency Across Batches:

Quality-controlled surfactants help maintain uniformity in every production batch, ensuring reliable product performance.

By focusing on quality and compliance, manufacturers can produce safe and dependable pharmaceutical formulations. Careful use of tyloxapol USP supports both regulatory requirements and product reliability.

Smart Choices for Reliable Pharma

Maintaining stability and consistency in pharmaceutical formulations often depends on the careful use of tyloxapol USP. It helps ensure that ingredients remain well-integrated and products perform as intended.

For manufacturers looking for dependable excipients, Lab Chemicals offers certified tyloxapol that meets rigorous industry standards. Our products help maintain safety, formulation integrity, and compliance throughout the production process.

Proper handling of 25301 02 4 enables us to achieve repeatable results across batches. We focus on precision and careful application, ensuring that every formulation remains reliable, consistent, and effective for end users.